ESSVEE GLASURS

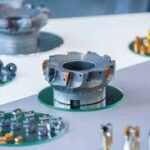

India’s Best PVD Coating for Cutting Tools Services

Services Provided

Pan India

Years Experience

About ESSVEE GLASURS

Our CEO Dr. Jayaramu, former President of the Peenya Industry Association, who has also worked as a scientist at ISRO under Thermal systems division-Surface treatment group embodied a vision for innovation and longevity in surface coatings.

Driven by a deep understanding of industry needs and a commitment to excellence. ESSVEE GLASURS offers a unique and patented solution for cutting tools to enhance their performance.

With a focus on quality and durability, our coatings are engineered to meet the highest standards, ensuring both aesthetic appeal and long-lasting performance. Backed by years of experience and expertise in industry proven coatings, ESSVEE GLASURS is poised to redefine the industry landscape, providing customers with superior products and unparalleled service.

We Provide Services for…

Aerospace

Medical

Automobile

Industrial Use

Electronics

What Makes ESSVEE GLASURS The Best for Cutting Tools PVD Coating

ESSVEE GLASURS was established with aim to enhance the performance of cutting tools and components by applying in house developed and patented coating for cutting tools recipes to meet modern machining conditions.

Longer tool life

Increased productivity

Uniform thickness

Corrosion resistant in PVD Coating for cutting tools

Thermally and chemically stable. Not affected by most acids and alkalis.

Lower maintenance costs

Check Out Our Durable Coatings

AlcronitE

AltinitE

AuronitE

TisinitE

TisinitE-Pro

Tools Coated

Technologies Are Ever-Evolving

And We Provide You With Industry Proven Coatings

Cost Effective Production

Enhanced Productivity

Reliable Manufacturing

ESSVEE GLASURS’s PVD coating for cutting tools are used with higher cutting parameters than the bear tools and ensures higher tool life. Higher cutting parameters improve productivity by reducing cutting times and the cost. More tool life means less replacement of tools and reduced setup of machine cost. Hence the coated tools ensure the reduced manufacturing cost.

Wondering How Coating Is Done?

Pre Treatment

Coating

Arc PVD coating involves vaporizing a target material using an electric arc in a vacuum, depositing thin films onto substrates. This plasma-based process ensures strong adhesion, resulting in durable coatings. At ESSVEE GLASURS we use industry proven tecnique for Coating